Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

- Wechat ID: lcj391509517 Email: info@nbearth-star.com

products

New products

-

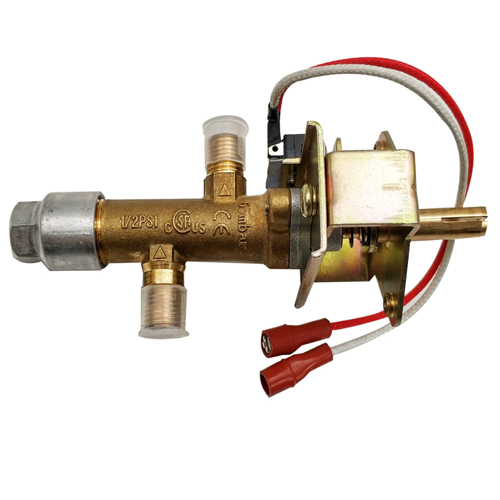

Flame Safety Valve with Bracket

Model.:SMT-FM009

-

5/8- 18NUF 8MM Shaft Brass Valve

Model.:SMT-FM009G

-

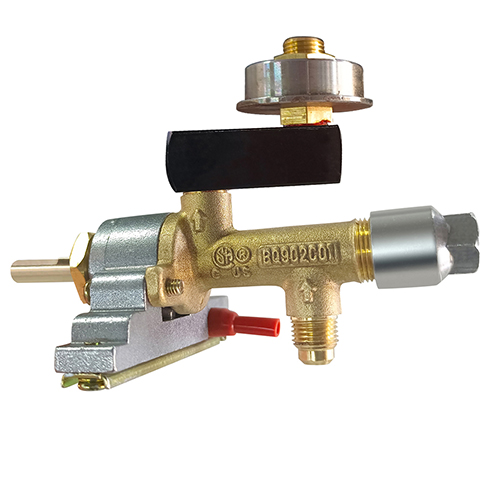

Patio Heater brass valve 2 Way

Model.:SMT-FM009F

-

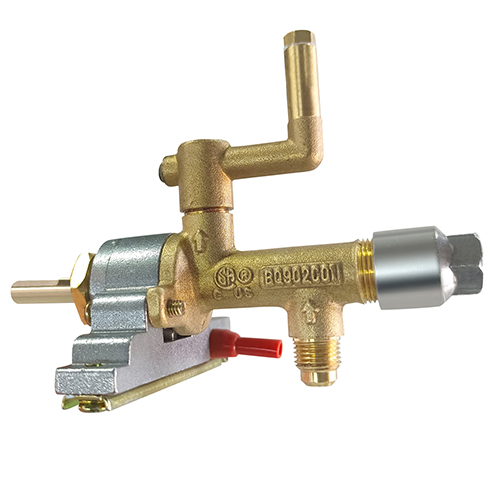

Outdoor Patio Heater gas valve (elbow with nozzle)

Model.:SMT-FM009L-1/WTJ001

-

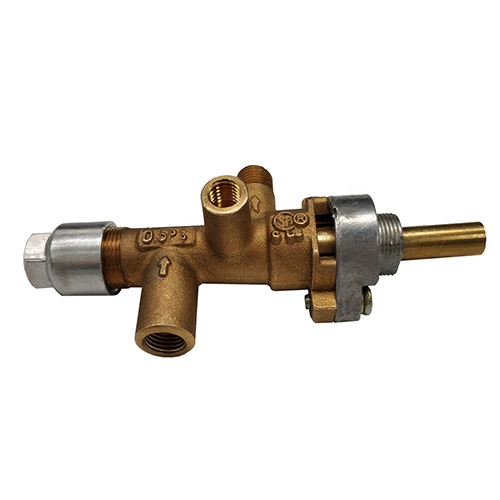

Copper valve inlet and outlet thread 7/16-24

Model.:SMT-FM009L

-

micro switch type gas valve for heater

Model.:SMT-FM008

alumium casting

Model NO.:ESST-009

Alumium foundry venturi burner *Different size for option * Small order quantity is acceptable *Customized Design is acceptable * 15 more years experience

Material: Alumium Process: Alumium Foundry Dimension: BSP1"*BSP1/4" thread,BSP1/2"*1/8" The metal plates require preheating in the early stages of the firing. This can be achieved with gas burners, or even a wood fire. Once the firebox has got hot the radiant heat will keep the plates hot and the burner becomes more efficient the hotter these plates become. Working principle

There is a definite ratio between the burner port area and the venturi throat. Typically, depending on the kiln or furnace back pressure, gas pressure and burner head design, the venturi throat area should be approx. 40-50% of the total burner port area. Mismatching may result in a decrease in mixture velocity producing inadequate burning or at worst "flash back". Low rates can be achieved by using a preheat pilot.