Product successfully added to your shopping cart

Quantity

Total

There are 0 items in your cart. There is 1 item in your cart.

Total products

Total shipping Free shipping!

Total

- Wechat ID: lcj391509517 Email: info@nbearth-star.com

products

New products

-

Flame Safety Valve with Bracket

Model.:SMT-FM009

-

5/8- 18NUF 8MM Shaft Brass Valve

Model.:SMT-FM009G

-

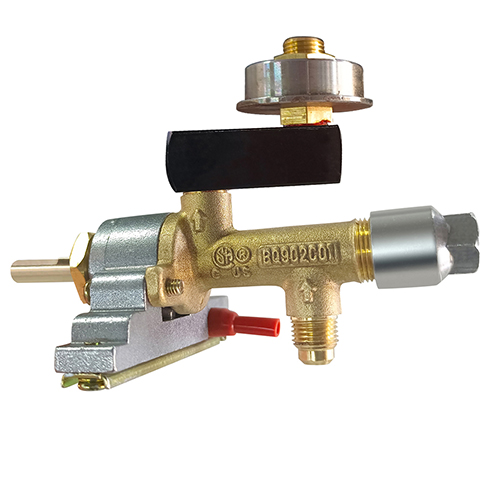

Patio Heater brass valve 2 Way

Model.:SMT-FM009F

-

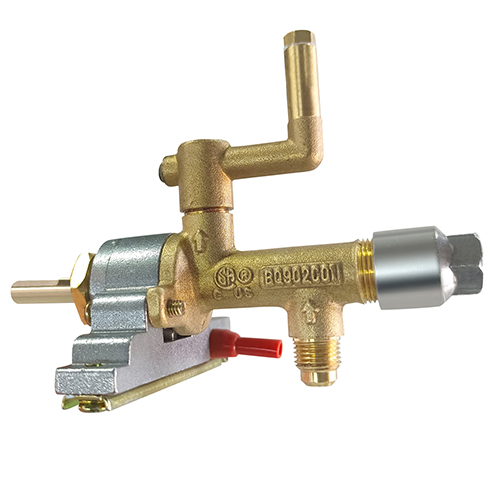

Outdoor Patio Heater gas valve (elbow with nozzle)

Model.:SMT-FM009L-1/WTJ001

-

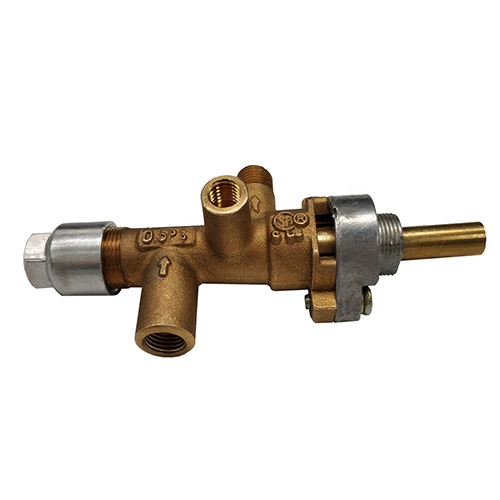

Copper valve inlet and outlet thread 7/16-24

Model.:SMT-FM009L

-

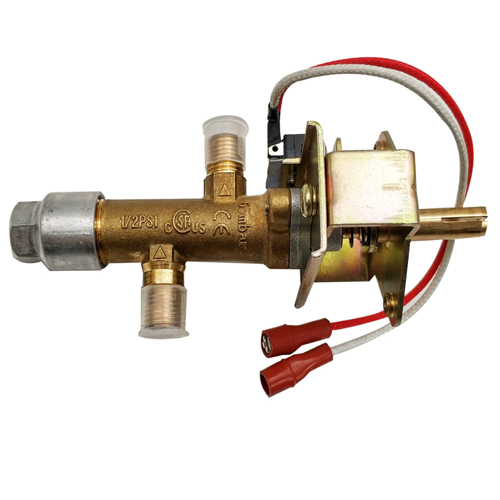

micro switch type gas valve for heater

Model.:SMT-FM008

News Center

What is the difference between gas battery igniter and piezoelectric ceramic igniter

Date:2016/10/25

Description

As we all know ,gas battery igniter and piezoelectric ceramic igniter is a importane part for gas stove . But what is battery igniter and piezoelectric ceramic igniter ? do you know the difference between gas battery igniter and piezoelectric ceramic igniter ? Today I would like to share the information with you .

Ignition devices, gas stove ignition commonly used spark ignition method, the ignition devices are mainly piezoelectric ceramic igniter, pulse igniter.

2. The pulse igniter uses the dry battery as the power source, the high voltage component uses the transistor as the oscillation element or uses the manifold to make the oscillation component; Also includes the pulse switch, the burner fire hole, the ignition needle, the high-tension wire, the ground discharges the terminal. The working process is: press the knob, so that the knob with the pulse switch connected to the high-voltage components after power, resulting in high-voltage discharge from the high-voltage line to the ignition needle, resulting in continuous discharge ignition, with the knob rotation, the main burner nozzle open , Gas from the fire hole out of being lit. Piezoelectric ceramic igniter has the advantage of long life, no other power, in the wet high heat to work properly. The disadvantage is that only one spark out of a spark. The advantages of the pulse igniter is the continuous spark when the ignition, the ignition rate is high, safe and reliable. Disadvantage is easy to damage after damp; to keep clean, dry; ignition spark small, to be replaced battery; long-term outage stove to be out of the battery.

If you still feel trouble , pls feel free to contact us .