Product successfully added to your shopping cart

Quantity

Total

There are 0 items in your cart. There is 1 item in your cart.

Total products

Total shipping Free shipping!

Total

- Wechat ID: lcj391509517 Email: info@nbearth-star.com

products

New products

-

Flame Safety Valve with Bracket

Model.:SMT-FM009

-

5/8- 18NUF 8MM Shaft Brass Valve

Model.:SMT-FM009G

-

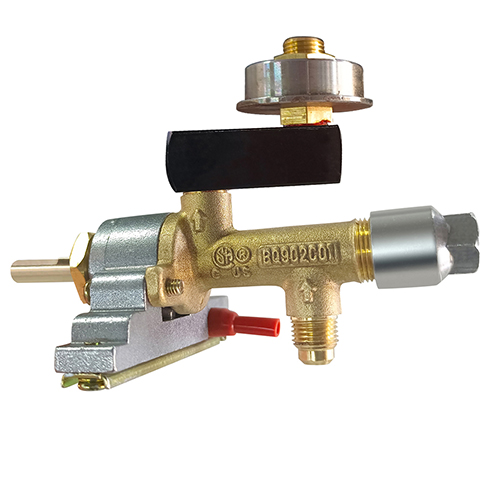

Patio Heater brass valve 2 Way

Model.:SMT-FM009F

-

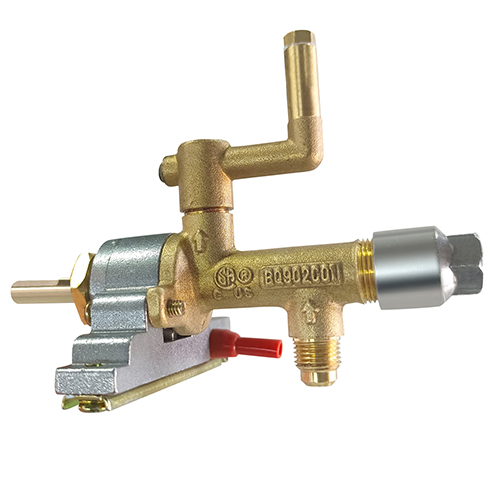

Outdoor Patio Heater gas valve (elbow with nozzle)

Model.:SMT-FM009L-1/WTJ001

-

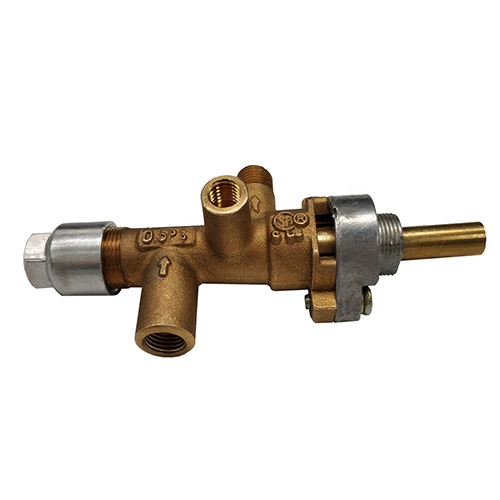

Copper valve inlet and outlet thread 7/16-24

Model.:SMT-FM009L

-

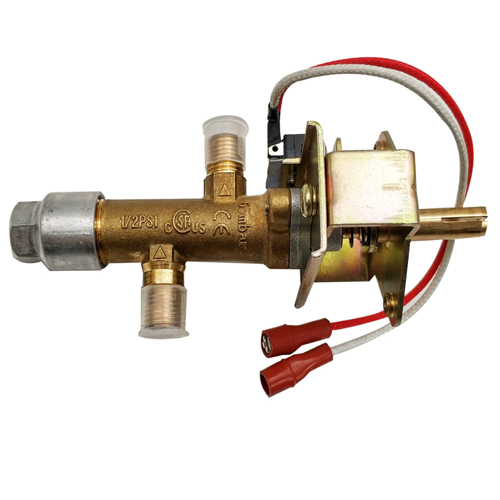

micro switch type gas valve for heater

Model.:SMT-FM008

News Center

Piezo electric ceramic igniter

Date:2016/11/25

Description

Piezoelectric

ceramic igniter is mainly dependent on the piezoelectric effect of the

ceramic components, the mechanical energy into electrical energy,

instantaneous discharge, discharge spark ignition gas. It

consists of high-voltage ignition needle, high-pressure rubber wire,

piezoelectric ceramic, hammer, reset spring, shell and other components

(see Figure 4-02). Piezoelectric

ceramic is mainly composed of lead-cobalt titanate as the raw material

of ceramic materials, by the molding, sintering, the electrode, a series

of polarized process made of columnar ceramics. The

arrangement of positive and negative ions on the ceramic lattice is

non-centrosymmetric, so that a potential difference (voltage) is

generated between the two ends of the ceramic under external force. The

resulting voltage level and the external force and the piezoelectric

ceramic is proportional to the height, inversely proportional to the

ceramic cross-section. Igniter

is two geometric shape with the pressure ceramic connected to the

cathode, with high-pressure rubber stranded copper wire leads to the

cathode with two copper face, the use of polycarbonate plastic seal,

easy to piezoelectric ceramic multiple impact . When

the knob is pushed and rotated, the knob lever moves the fork on the

spool to move the hammer in the igniter and the hammer return spring is

compressed. When the knob rotates to 90 °, Under

the action of the spring force, the hammer hits the negative pole of

the piezoelectric ceramic and generates the instant high voltage (15KV)

at the other end (positive pole). The ignition ignites the ground

discharge.